SMD Micro-Resistance Precision Alloy Shunt Resistors in Automotive Battery Management Systems (BMS)

Overview

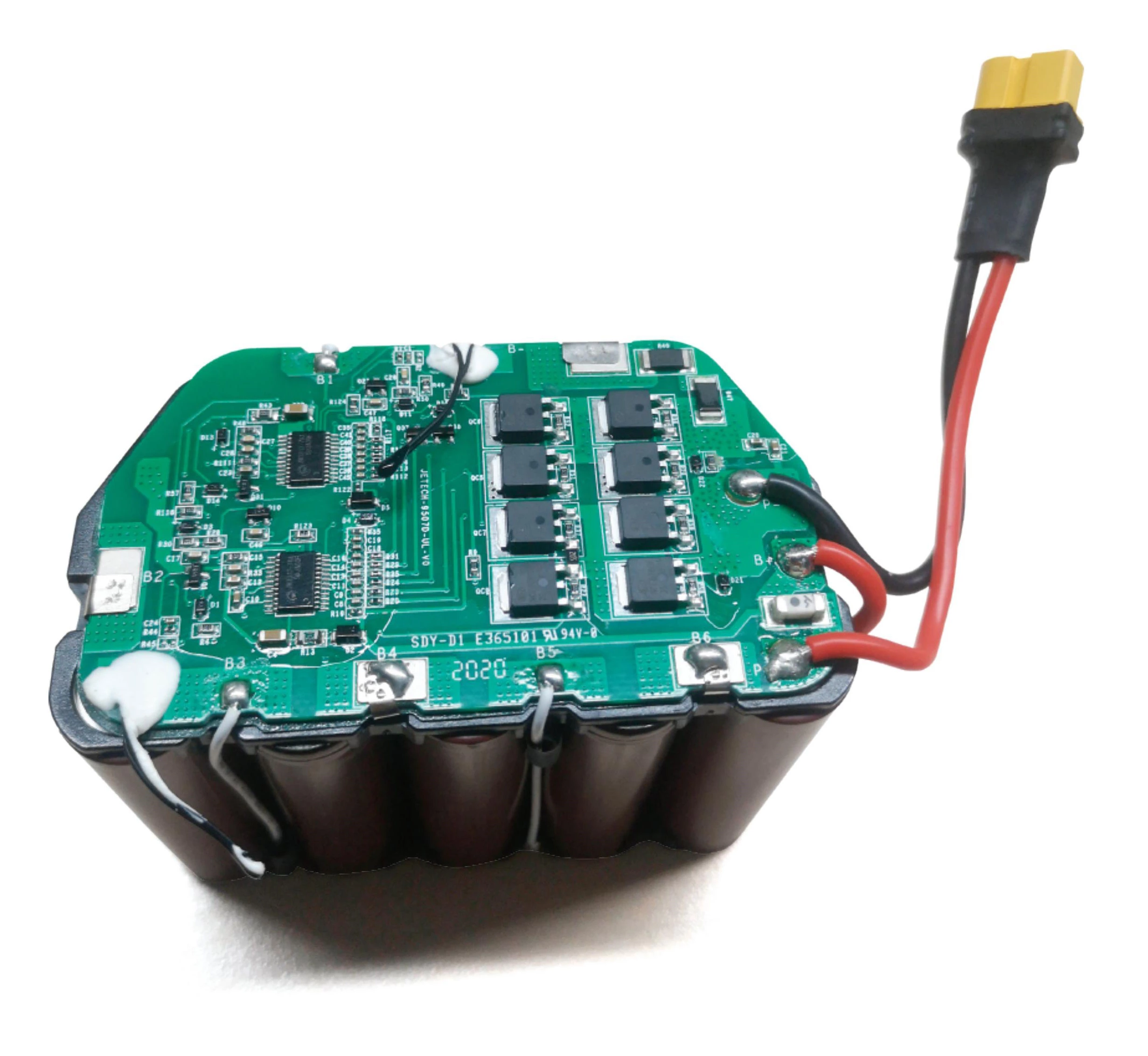

As electric vehicles (EVs) and hybrid electric vehicles (HEVs) become more popular, battery management systems (BMS) play an increasingly important role in ensuring the safety, efficiency, and life of automotive batteries. The BMS is responsible for monitoring key parameters such as the state of charge (SOC), state of health (SOH), temperature, and voltage of each battery cell. To accurately perform these tasks, the BMS relies on real-time data, including precise current measurements.

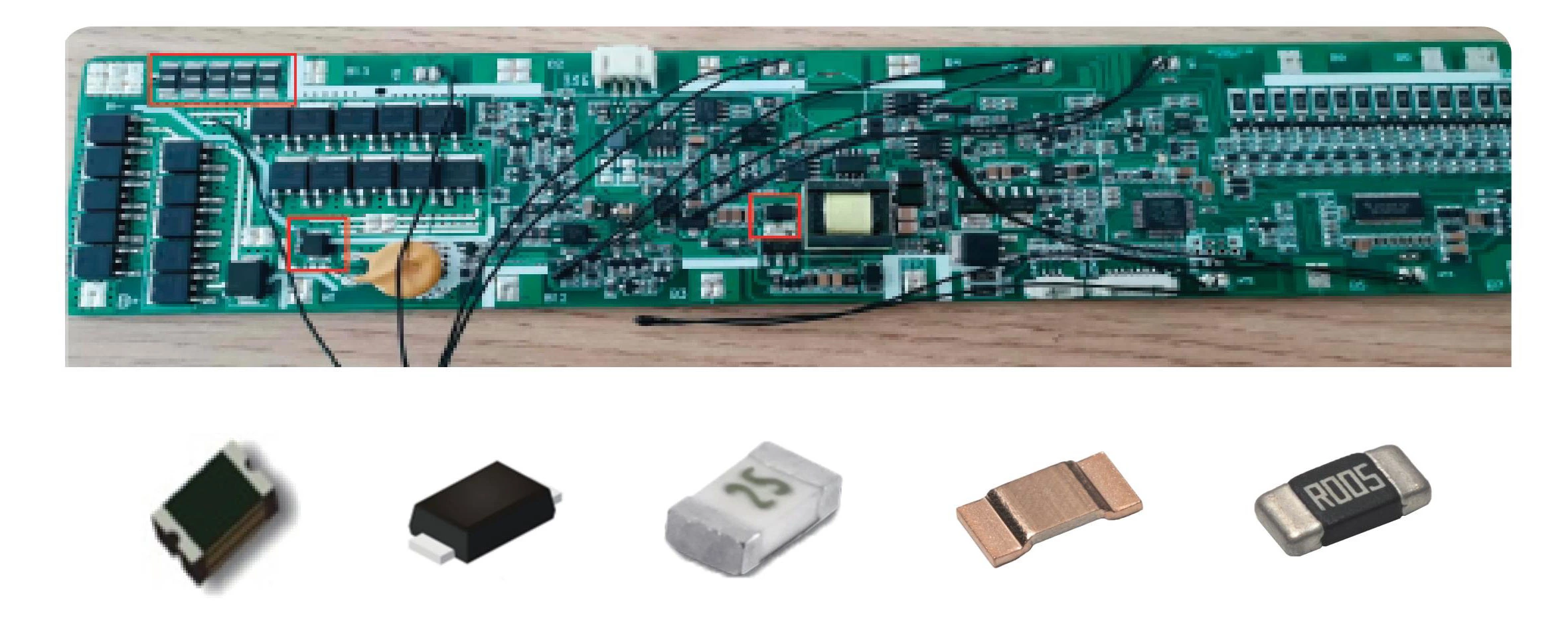

One of the key components in an automotive BMS to achieve these measurements is the SMD (Surface Mount Device) microresistance precision alloy shunt resistor. These resistors are used to accurately measure the battery's charge and discharge current, ensuring the system operates within a safe range, optimizing energy use and extending battery life.

The role and application of SMD micro-resistance precision alloy shunt resistor in BMS

SMD Microresistors precision alloy shunt resistors are ideally suited to meet the stringent requirements of automotive battery management systems (BMS). These resistors are used to monitor the charge and discharge current of the battery, enabling the BMS to calculate important parameters such as state of charge (SOC) and state of health (SOH). Below are some specific applications where these resistors are used in BMS systems.

1. Current measurement of state of charge (SOC)

The state of charge (SOC) indicates the amount of charge remaining in the battery, providing important data for range prediction, energy management, and preventing overcharging or undercharging. SOC is typically calculated by integrating the current over time, which requires continuous and accurate current sensing.

Application: Shunt resistors are placed in the charge/discharge path of a battery pack to measure the current flowing into and out of the battery. The precise voltage drop across the shunt resistor is used to calculate the current and then used to update the SOC.

Role of the resistor: The low tolerance (±0.1% or better) and low TCR (temperature coefficient of resistance) of the precision alloy shunt resistor ensures accurate measurement even with temperature fluctuations, preventing errors in SOC calculations. This helps maximize battery efficiency and prevents overcharging or discharging, which can damage the battery.

2. Monitoring State of Health (SOH)

The state of health (SOH) of a battery refers to its ability to hold a charge relative to when it was new. SOH is determined by monitoring the degradation of battery performance over time, including loss of capacity, increase in internal resistance, and other factors that affect battery life.

Application: Shunt resistors are used to track the charge and discharge current over the life of a battery. By monitoring the voltage drop across the shunt resistor, a gradual increase in internal resistance can be detected, providing data on battery degradation.

The role of the resistor: SMD micro-resistance precision alloy shunt resistors have high stability and reliability, ensuring that the BMS can continuously monitor the performance of the battery without introducing measurement errors, even as the battery ages. This helps the BMS accurately predict the remaining life of the battery and optimize the charging cycle.

3. Cell Balancing

In a battery pack containing multiple cells, it is important to ensure that each cell charges and discharges evenly to maximize overall battery performance and life. Cell balancing ensures that all cells in the pack maintain similar voltage and charge levels.

Application: Shunt resistors are used in conjunction with cell balancing circuits to measure the current flowing through each cell. By monitoring the current, the BMS can detect if any cell is charging or discharging at a different rate than the other cells and adjust the charge current to bring them into balance.

Resistors’ Role: Precision alloy shunt resistors have the necessary high accuracy and low drift characteristics to accurately monitor the current of each cell. This enables the BMS to perform effective cell balancing, thereby extending the service life of the entire battery pack.

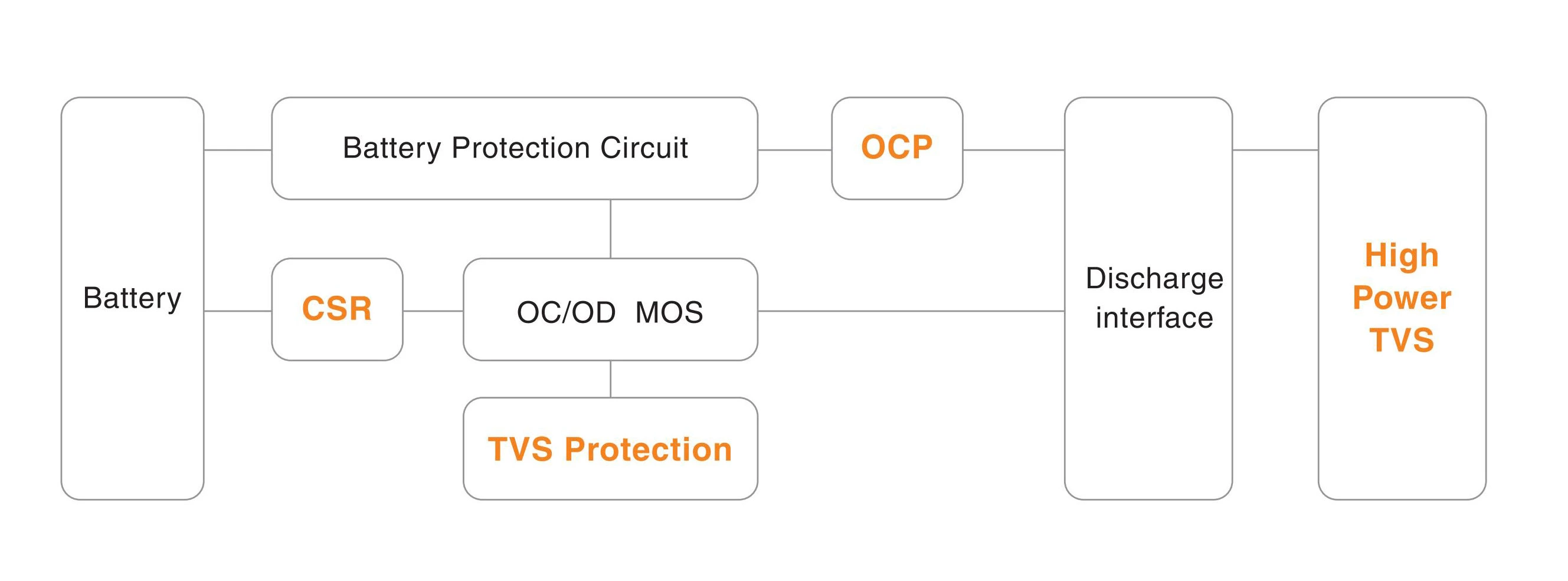

4. Overcurrent protection and safety

The BMS is responsible for protecting the battery from dangerous overcurrent conditions that could cause overheating, thermal runaway, or even fire. Shunt resistors are used to continuously measure the current to detect any abnormal increase in current that could indicate a fault.

Application: A shunt resistor is placed in series with the battery to measure the current flow over time. The BMS uses this information to trigger safety protocols such as cutting off the charge or discharge current in the event of an overcurrent condition.

Resistor Role: High power handling and temperature stability are the main features of SMD Microresistors precision alloy shunt resistors, ensuring they can withstand high currents without failure. They also provide reliable feedback to the BMS, helping to prevent dangerous situations by triggering protection circuits when needed.

Main advantages of SMD micro resistors precision alloy shunt resistors in BMS

1. High precision and high accuracy

- With tolerances as low as ±0.1% and low temperature coefficient, SMD Microresistors precision alloy shunt resistors provide accurate current measurement required for SOC, SOH and cell balancing in BMS.

2. Temperature stability

- These resistors maintain stable performance over a wide temperature range, ensuring that the BMS continues to operate accurately in both cold and hot automotive environments.

3. Compact size and integration

- The SMD form factor is ideal for compact and space-constrained automotive BMS designs, allowing the integration of high-precision resistors without taking up too much space.

4. Durability and reliability

- The automotive environment subjects BMS components to thermal cycling, vibration and other stresses. SMD shunt resistors are designed for high reliability and long-term durability to ensure consistent performance throughout the life of the vehicle.

5. Cost-effective manufacturing

- SMD precision alloy shunt resistors are manufactured using a scalable process that is cost-effective while maintaining high quality and performance - critical for mass-market electric vehicle production.

in conclusion

As the automotive industry transitions to electric vehicles, the importance of efficient and reliable battery management systems (BMS) has become increasingly prominent. SMD microresistors precision alloy shunt resistors play a vital role in achieving accurate current sensing, which enables key functions such as state of charge (SOC), state of health (SOH) monitoring, cell balancing and overcurrent protection.

From a resistor manufacturer’s perspective, we see a growing demand for high-precision, compact, and durable resistors that can withstand the rigors of the automotive environment. Our precision alloy shunt resistors provide the accuracy, reliability, and thermal stability required for next-generation BMS in electric and hybrid vehicles, helping to improve the performance and safety of battery systems.

Through continuous innovation in precision current sensing, we aim to support the development of more efficient, safer, and longer-lasting electric vehicle battery systems, contributing to the overall advancement of the automotive industry.