Precision Low-Resistance Alloy Resistors in Automation Control Systems

Overview

In the modern industrial landscape, automation control systems are integral to achieving high levels of efficiency, precision, and reliability in manufacturing, process control, robotics, and a wide range of other automated applications. Automation systems rely on a vast array of components, including sensors, actuators, control circuits, and power management systems, all of which must work together seamlessly to maintain consistent, accurate, and responsive operations.

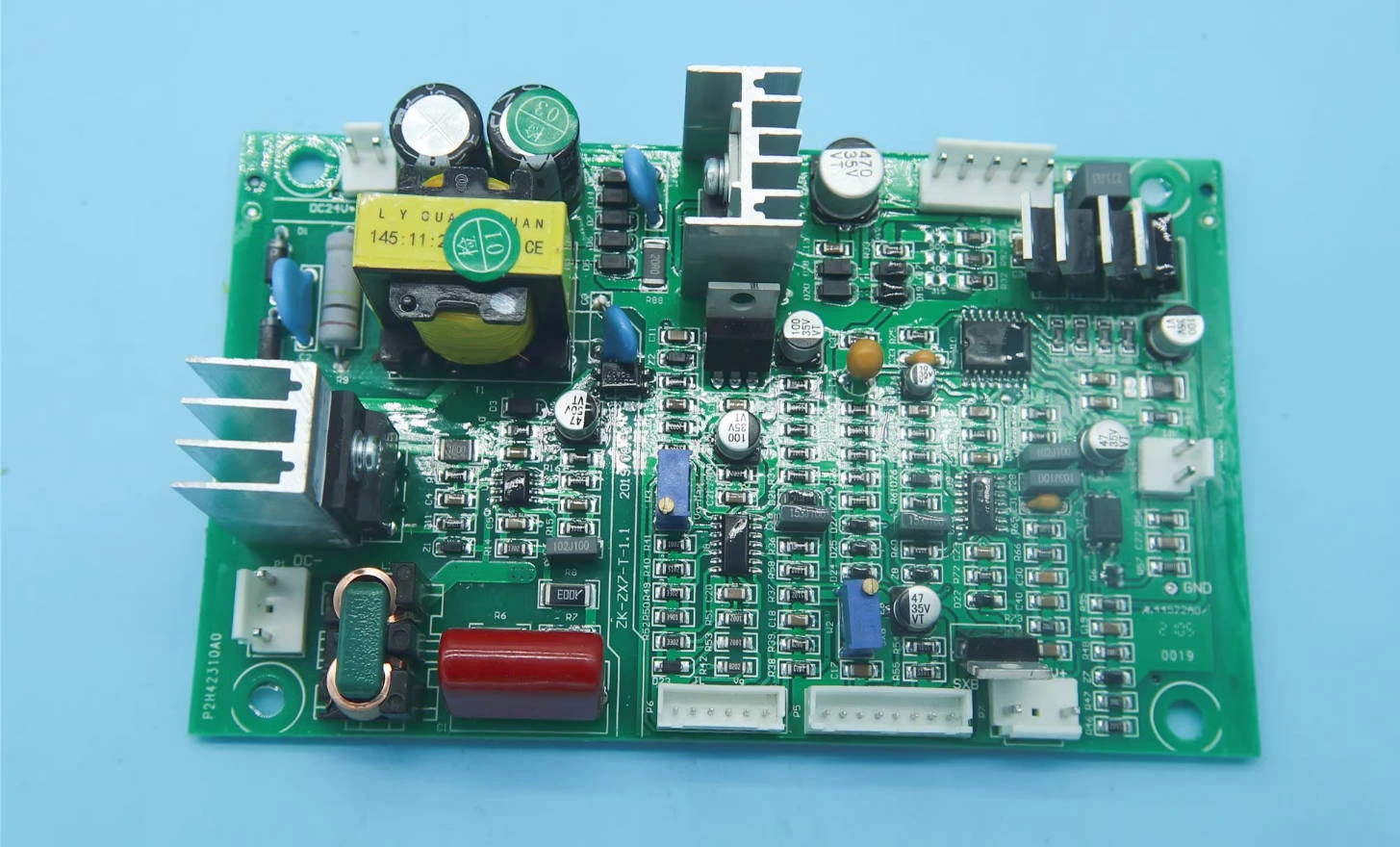

At the heart of many of these systems are precision components like precision low-resistance alloy resistors, which ensure the accurate measurement and control of electrical signals. These resistors are used in a variety of applications, such as current sensing, voltage regulation, temperature monitoring, feedback loops, and power control. Their role in providing reliable, stable performance in harsh industrial environments makes them a crucial part of automation control systems, where precision and reliability are paramount.

This case study explores the application of precision low-resistance alloy resistors in automation control systems from the perspective of a resistor manufacturer, highlighting their importance in ensuring system stability, accuracy, and long-term operational success.

The Role of Precision Low-Resistance Alloy Resistors in Automation Control Systems

Automation control systems rely on real-time data to monitor, analyze, and control industrial processes. Precision low-resistance alloy resistors are used to provide critical measurements for current sensing, voltage regulation, temperature monitoring, and feedback control, all of which are vital for the proper functioning of these systems. These resistors offer high accuracy, low tolerance, and superior thermal stability, ensuring optimal performance even in demanding industrial environments.

1. Current Sensing in Motor Control Systems

One of the most common applications for precision low-resistance alloy resistors in automation control systems is in motor control. Motors drive many industrial processes, and precise control of motor current is essential to ensure optimal performance, efficiency, and protection. Current sensing resistors are used to monitor the current flowing through the motor windings and provide real-time feedback to the motor control unit (MCU), allowing for dynamic adjustment of motor speed, torque, and power.

- Current Monitoring: Precision resistors are placed in series with motor circuits to provide accurate feedback on the current drawn by the motor. This allows for real-time monitoring of motor performance and helps prevent issues such as overcurrent or stalling.

- Overcurrent Protection: If the motor current exceeds safe thresholds, the system can trigger protective actions such as limiting power or shutting down the motor to prevent damage.

- Example: In a robotic arm control system, precision resistors are used to monitor the current consumed by the electric motors driving the arm’s joints. By measuring current in real-time, the system can adjust motor performance based on load conditions and prevent overheating or damage from excessive current.

- Benefits:

- Accurate motor control: Ensures precise regulation of motor speed and torque, improving system performance.

- Enhanced protection: Prevents damage to the motor and surrounding components by detecting and responding to overcurrent conditions.

2. Voltage Regulation in Power Supplies

Many automation systems rely on stable and precise voltage to power sensitive electronics and actuators. Precision low-resistance alloy resistors are used in voltage regulation circuits to ensure that the voltage levels are consistently maintained within a safe operating range, which is critical for the longevity and stability of the control system.

- Voltage Sensing: Precision resistors are used in feedback loops of voltage regulators to ensure that the system maintains the correct voltage levels for different components of the automation control system, such as sensors, controllers, and actuators.

- Stable Power Supply: These resistors contribute to maintaining voltage stability, reducing the likelihood of voltage spikes or drops that could disrupt system performance.

- Example: In a PLC-based automation control system, precision resistors are used in the DC-DC converter to maintain consistent voltage output, which is then supplied to various sensors, actuators, and control modules. This ensures that all components receive reliable power, enhancing the overall performance of the automation system.

- Benefits:

- Reliable power supply: Ensures consistent voltage, protecting sensitive components from power irregularities.

- Improved system stability: Reduces the risk of voltage-related errors or failures, enhancing overall reliability.

3. Temperature Monitoring and Thermal Protection

In automation control systems, particularly in high-power applications such as industrial machines and robotics, maintaining optimal temperature levels is critical. Precision low-resistance alloy resistors are used in thermal management systems to measure and monitor temperatures, ensuring that critical components do not overheat.

- Temperature Sensing: Precision resistors are used in thermistors or temperature-sensing circuits to provide real-time temperature measurements of motors, power supplies, or other heat-sensitive components.

- Thermal Protection: These resistors can trigger protective actions, such as turning on cooling systems or shutting down components when temperatures exceed safe operating thresholds.

- Example: In an automated CNC machine, precision resistors are used to monitor the temperature of the machine’s motor and power electronics. If the temperature exceeds safe limits, the system can automatically activate cooling fans or shut down the motor to prevent overheating and potential damage.

- Benefits:

- Prevents overheating: Ensures that components operate within safe thermal limits, preventing damage and extending component lifespan.

- Efficient thermal management: Enables quick response to temperature fluctuations, ensuring optimal system performance.

4. Feedback Control in Closed-Loop Systems

Many automation control systems operate in closed-loop configurations, where real-time feedback is used to adjust system parameters dynamically. Precision low-resistance alloy resistors are essential in these systems to provide accurate feedback on current, voltage, and temperature, allowing the controller to make adjustments that optimize performance.

- Feedback Loops: These resistors are used to sense the output parameters, such as motor speed, actuator position, or power consumption, and provide feedback to the control unit. This data is then used to adjust the system inputs to maintain desired performance.

- Dynamic Adjustments: Precision resistors help the system make fine adjustments in real time, ensuring that the automation process is always operating within optimal parameters.

- Example: In an automated packaging line, precision resistors are used in feedback circuits to monitor the speed of the conveyor belt and adjust the motor's speed in real-time, ensuring that the system operates at the desired throughput rate without overloading.

- Benefits:

- Accurate control: Provides precise feedback for real-time adjustments, ensuring that processes remain efficient and within specifications.

- Optimized performance: Enhances the responsiveness of the system, improving productivity and reducing energy consumption.

5. Power Management in Distributed Control Systems

In larger automation systems, especially those with distributed control networks (e.g., factory automation systems or smart grid applications), managing the distribution and consumption of electrical power is crucial. Precision low-resistance alloy resistors are often used in power management circuits to ensure that each component in the system receives the correct amount of power.

- Power Distribution: Precision resistors are used to measure the current and voltage in different parts of the control network, allowing the system to optimize the distribution of power across components.

- Load Balancing: These resistors help prevent overload situations by monitoring the power consumption in real-time and adjusting the distribution of power across the network.

- Example: In a smart factory, precision resistors are used in the power management circuits of distributed control modules (DCMs) to monitor the power consumption of various machines and devices. This data is used by the central control system to balance loads and ensure that no individual device or system is overloaded.

- Benefits:

- Efficient power distribution: Ensures that power is distributed optimally across the system, preventing overloading and reducing energy waste.

- Improved load balancing: Increases the overall efficiency of the automation system, leading to energy savings and reduced operational costs.

#### Conclusion: Precision Low-Resistance Alloy Resistors in Automation Control Systems

Precision low-resistance alloy resistors are indispensable components in automation control systems, providing vital functions such as current sensing, voltage regulation, temperature monitoring, feedback control, and power management. These resistors ensure the stability, accuracy, and reliability of automation systems by offering low tolerance, high stability, and resilience to environmental stresses.

As a resistor manufacturer, we offer high-performance precision resistors tailored to meet the demanding requirements of automation control systems. Our resistors are designed to handle high currents, resist thermal fluctuations, and operate reliably in industrial environments, ensuring optimal performance of motors, controllers, sensors, and actuators.

By integrating our precision resistors into automation control systems, manufacturers can achieve enhanced performance, improved energy efficiency, reduced downtime, and longer component lifespans. Our resistors play a key role in enabling the next generation of intelligent manufacturing, where automation systems are more precise, efficient, and responsive than ever before.

In today’s fast-evolving industrial landscape, precision low-resistance alloy resistors are an essential enabler of the smart, connected automation systems that will drive the future of manufacturing, energy management, and industrial operations.